3D scanning and reverse engineering

We support customers in Saarbrücken, Saarlouis, Neunkirchen, Völklingen, Homburg and the entire Saar-Lor-Lux region.

How can this change the world?

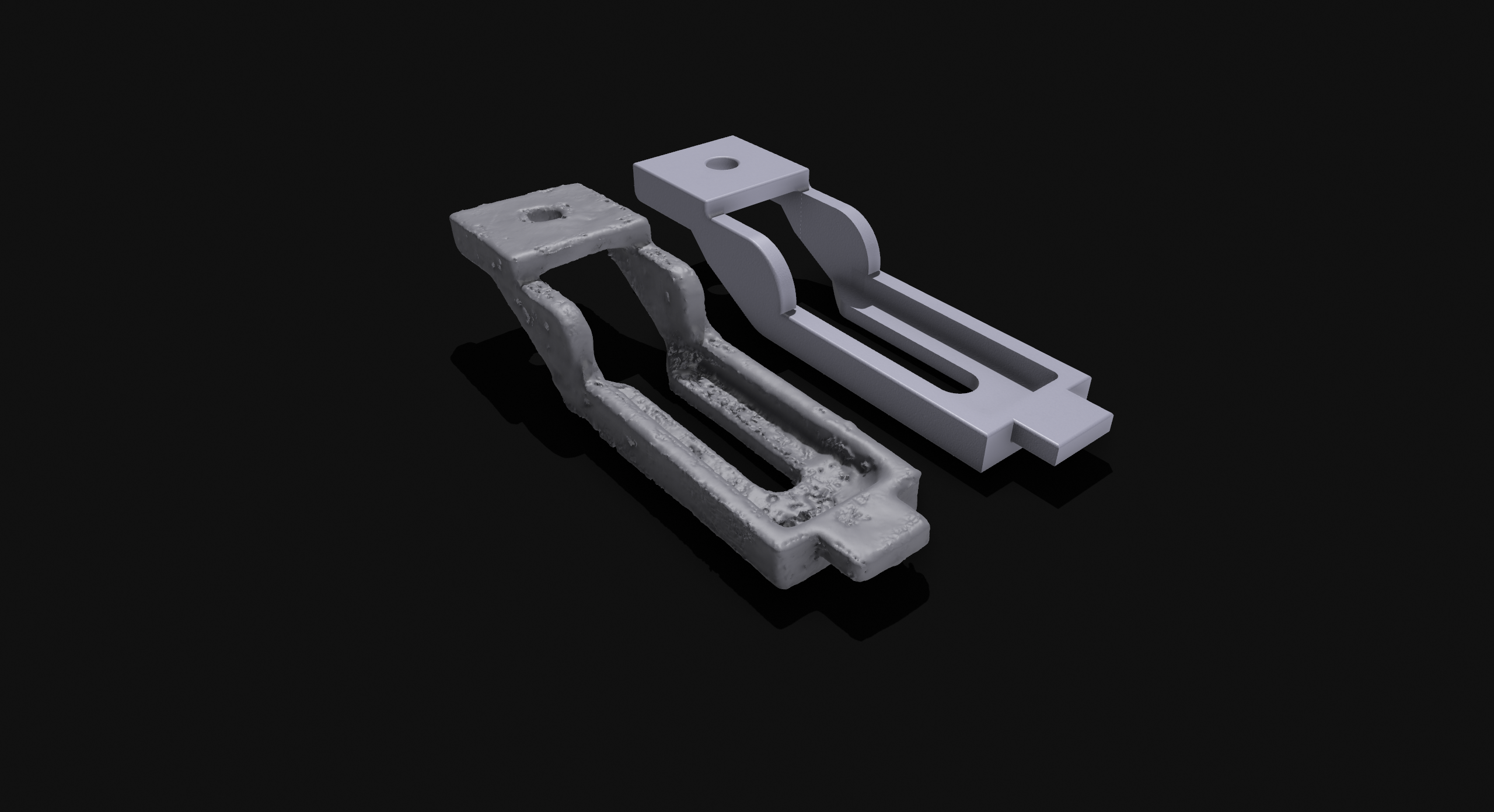

3D scanning, reverse engineering and spare parts production

In modern manufacturing, 3D scanning and reverse engineering play a crucial role, especially in the production of spare parts.

By using advanced 3D scanners, existing components can be precisely digitized, even if no CAD data is available.

This enables the creation of a digital twin that serves as the basis for product optimization, prototype production and quality assurance.

The process of reverse engineering using 3D scanners involves several, sometimes complex, manual steps:

- Data collection :

The geometry of the existing component is recorded using 3D scanners.

- Data processing :

The scanned data is converted from a point cloud into CAD models, which requires one or two sometimes time-consuming interventions.

These files can then be used for design or manufacturing.

- Production :

Based on the CAD models, spare parts can be manufactured using additive manufacturing technologies such as 3D printing.

With existing spare parts databases, within the shortest possible time and worldwide on any suitable printer.

This approach offers several advantages:

• Fast spare parts procurement : Through digitalization and subsequent manufacturing, spare parts can be produced promptly, which reduces downtime.

• Cost efficiency : The need for expensive tools or molds is eliminated, which saves costs especially for small series or individual pieces.

• Flexibility : Adjustments and optimizations can be made directly to the digital model without having to create physical prototypes.

Overall, 3D scanning and reverse engineering enable efficient and precise production of spare parts, even with complex geometries or missing original data.

As with any technology, there are limits that shift very quickly in this area.

Anyone who knows these limitations can find solutions in many areas using 3D printing.

This ensures that companies can maintain their operational capability while saving costs, time and energy.

Curious or already have a specific problem?

Talk to us …